Comprehensive corrosion engineering for storage tanks, extending asset life through advanced surface preparation and marine-grade coating systems

Explore Our SolutionsWe specialize in comprehensive tank corrosion engineering solutions for petrochemical storage facilities. Our expert team delivers complete tank maintenance services including surface preparation, advanced coating systems, internal structure protection, and rigorous quality assurance protocols that meet international standards.

Our proven track record includes major projects for leading petrochemical companies. We provide turnkey solutions from pre-mobilization through final handover, ensuring minimal downtime and maximum asset protection. Our comprehensive approach addresses shell and roof protection, internal structures, access systems, and performance validation through advanced testing methods.

Full-scope corrosion engineering from surface prep to final coating

Multi-point inspection and adhesion testing protocols

State-of-the-art blasting and coating application systems

Our comprehensive pre-mobilization process ensures all equipment and materials are thoroughly prepared, inspected, and ready for deployment. This critical phase includes detailed planning, equipment verification, and logistics coordination to guarantee seamless project execution.

We maintain a complete inventory of specialized equipment including compressors, after coolers, hoppers, and blasting systems. All equipment undergoes rigorous pre-deployment inspection and testing. Our night-time preparation activities and systematic loading procedures ensure efficient mobilization with zero equipment failures on-site.

Strategic on-site deployment and facilities setup creates an efficient, safe, and organized work environment. Our systematic approach to site layout optimization ensures smooth operations throughout the project lifecycle.

We establish comprehensive on-site facilities including working sheds, storage containers, and organized equipment placement. Compressors, after coolers, and hoppers are strategically positioned for optimal workflow. Our organized site layout maximizes efficiency while maintaining strict safety and environmental compliance standards.

Our strategic equipment placement and facility setup maximizes workflow efficiency while maintaining safety compliance. Organized site layouts reduce project time and ensure seamless coordination between all work phases.

Advanced surface preparation and coating application for tank shells and roofs ensures long-lasting corrosion protection. Our multi-stage process combines precision blasting with high-performance coating systems designed for harsh petrochemical environments.

The process begins with thorough surface preparation including sweep blasting to remove existing coatings and corrosion. Tank shell blasting achieves optimal surface profile for coating adhesion. Following comprehensive surface prep, we apply specialized coating systems to both shell and roof structures, ensuring complete protection against corrosive elements and environmental exposure.

Internal tank structures require specialized corrosion protection due to constant exposure to stored products and moisture. Our comprehensive approach addresses all internal components including ladders, columns, and pipeline systems with advanced surface preparation and coating technologies.

We provide complete protection for all internal structures through systematic blasting and coating processes. Internal ladders and columns undergo thorough surface preparation before receiving high-performance coatings. Pipeline internals receive specialized treatment including internal blasting and coating application, ensuring complete corrosion protection from the inside out. Our before-and-after documentation demonstrates the dramatic transformation and protection achieved.

Our specialized internal structure protection addresses the unique challenges of confined spaces and complex geometries. Advanced blasting and coating systems ensure complete coverage and long-lasting protection for all internal components.

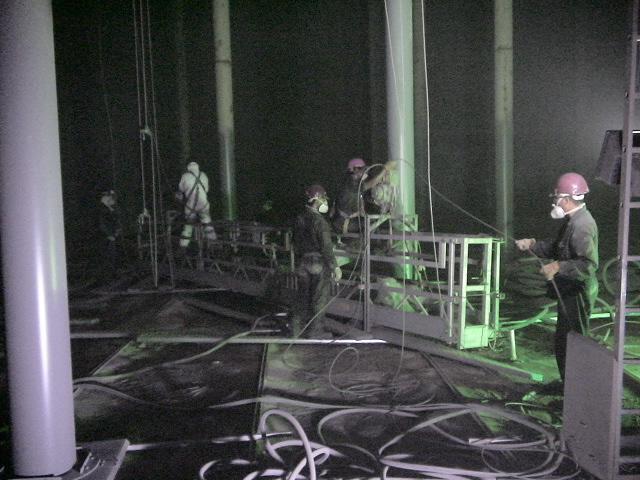

Safe access to tank roof undersides and elevated areas requires advanced rigging systems. Our spreader system gondola and davit systems provide secure, efficient access while maintaining the highest safety standards for workers performing critical coating and inspection tasks.

We deploy state-of-the-art spreader system gondolas that enable safe movement across tank roof undersides. The system is securely anchored to roof structures with comprehensive safety features. Our davit systems provide additional access points for complex areas. All access systems undergo rigorous safety inspections and are operated by certified personnel trained in high-access work protocols.

Rigorous quality assurance protocols ensure every aspect of tank corrosion protection meets or exceeds international standards. Our multi-point inspection process involves independent third-party verification and advanced testing methodologies at critical project milestones.

PPMSB inspectors conduct comprehensive verification of tank shell and roof coating application. Dry Film Thickness (DFT) inspections confirm proper coating thickness across all surfaces. DOSH and PPMSB inspections verify spreader system safety and compliance. Advanced CCTV inspection technology enables thorough examination of pipeline internals, ensuring complete coverage and protection in areas not accessible by visual inspection.

Our quality assurance program combines traditional inspection methods with advanced technologies including CCTV pipeline inspection and precision DFT measurement. Independent third-party verification ensures complete transparency and compliance with all regulatory requirements.

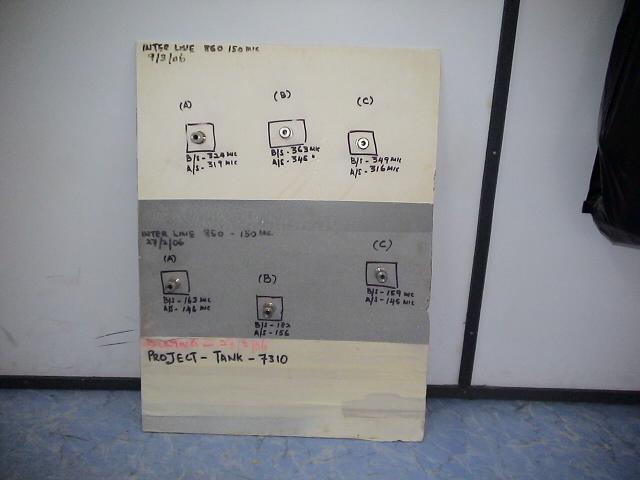

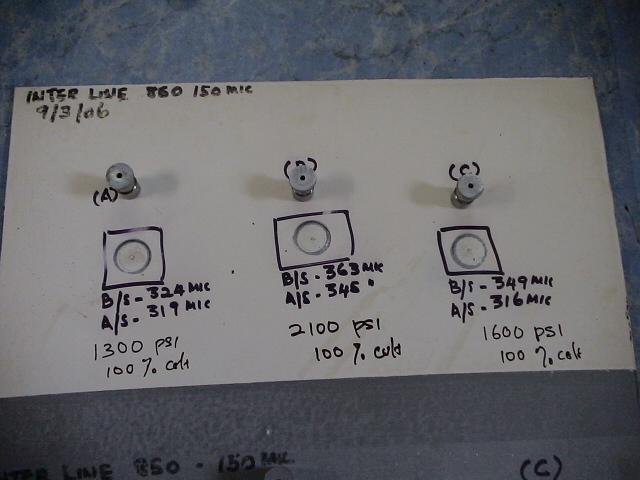

Adhesion pull-off testing provides quantitative validation of coating performance, ensuring the applied systems meet stringent adhesion requirements. This critical test verifies the bond strength between coating and substrate, confirming long-term protection reliability.

We conduct adhesion pull-off tests using calibrated equipment and standardized procedures. Test plates are mounted with precision dollies at strategic locations. Tests are performed under witness of inspectors and clients, providing transparent validation of coating performance. Successful test results, such as 1300 psi with 100% cohesive failure, demonstrate superior coating adhesion that exceeds industry standards and ensures decades of corrosion protection.

Successful project completion marks the culmination of meticulous planning, expert execution, and rigorous quality control. Our comprehensive handover process ensures clients receive fully protected assets with complete documentation and long-term maintenance guidance.

The final phase includes comprehensive site inspection, complete documentation package delivery, and formal handover procedures. Clients receive detailed as-built records, test results, coating specifications, and maintenance recommendations. Our projects, such as the T-7310 KEROSENE tank maintenance for PETRONAS, demonstrate our commitment to excellence and client satisfaction. We provide ongoing support and maintenance planning to ensure continued asset protection for decades to come.

Our comprehensive tank corrosion protection solution for PETRONAS's T-7310 KEROSENE storage tank demonstrates our full-scope capabilities. From pre-mobilization through final handover, we delivered complete corrosion engineering services including surface preparation, coating application, internal structure protection, safety systems, and quality validation—all completed on schedule with zero safety incidents.

Our tank corrosion engineering experts provide comprehensive solutions from surface preparation to final validation, ensuring long-term asset protection

Request a Consultation