Professional onboard corrosion treatment and coating services—while your vessel remains operational

No downtime required. Save costs. Extend asset lifespan.

Corrosion is a persistent challenge in the maritime industry, affecting critical areas such as hulls, ballast tanks, handrails, ladders, and pipelines. Traditional repair methods often require vessels to be drydocked or taken out of service, leading to significant operational downtime and lost revenue.

Ship owners and operators face a difficult choice: delay necessary maintenance and risk asset degradation, or accept costly downtime for repairs. This dilemma impacts profitability, safety, and the long-term integrity of maritime assets.

CORRAST's Marine Voyage Repairs service enables corrosion treatment and protective coating application while your vessel remains operational. Our specialized 3-person team boards your vessel with compact, portable equipment—including our advanced Aqua-Jet wet abrasive blasting system—and performs comprehensive repairs without interrupting your operations.

This innovative approach eliminates the need for drydocking or operational shutdown, allowing you to maintain schedules, meet commitments, and protect your assets—all at the same time.

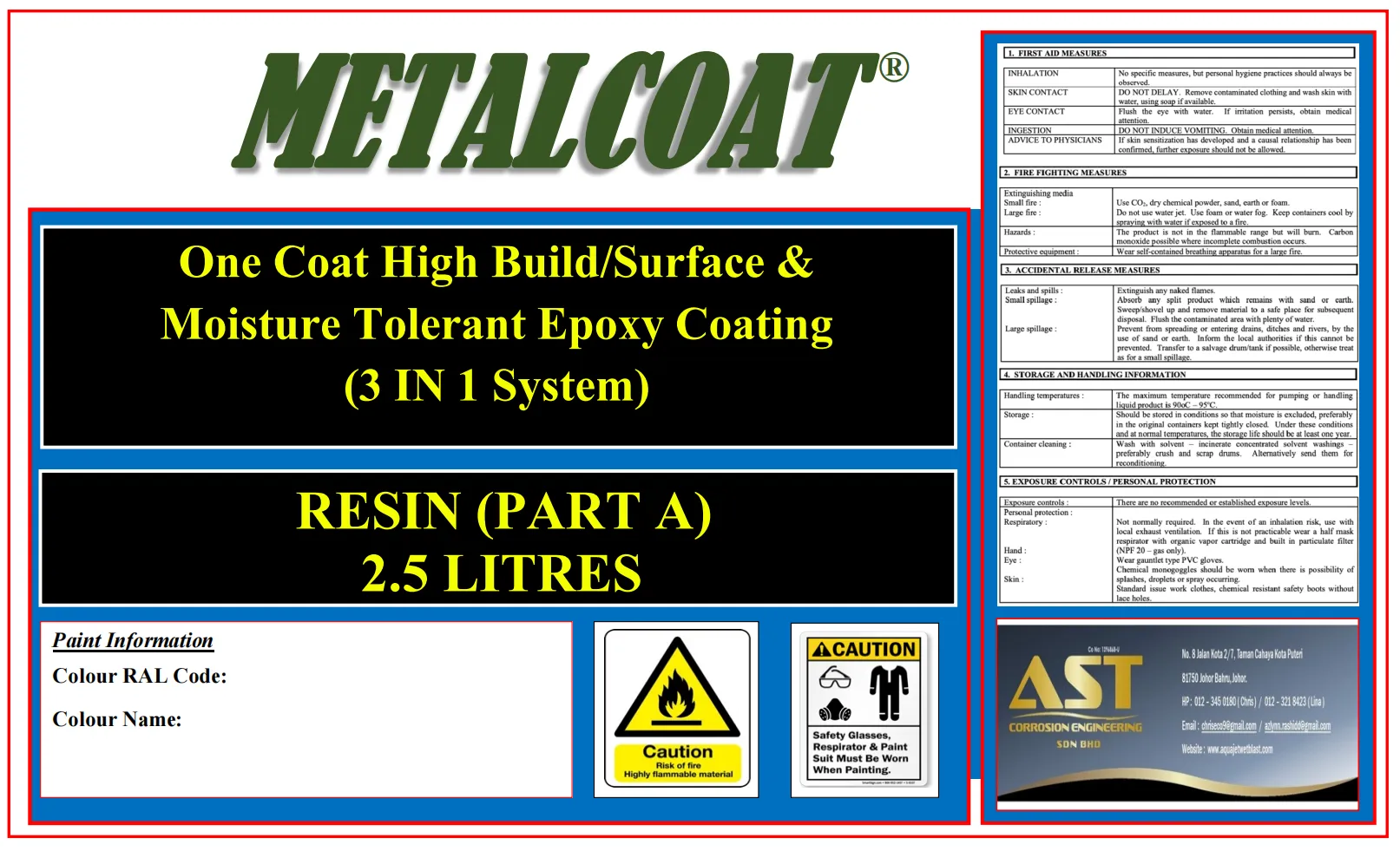

Our Metal-Coat Underwater Epoxy (UWE) is specifically formulated for challenging marine environments. This advanced coating system can be applied to wet, damp, or even fully submerged surfaces, making it ideal for ballast tanks, cargo tanks, bilges, and other areas where moisture is present.

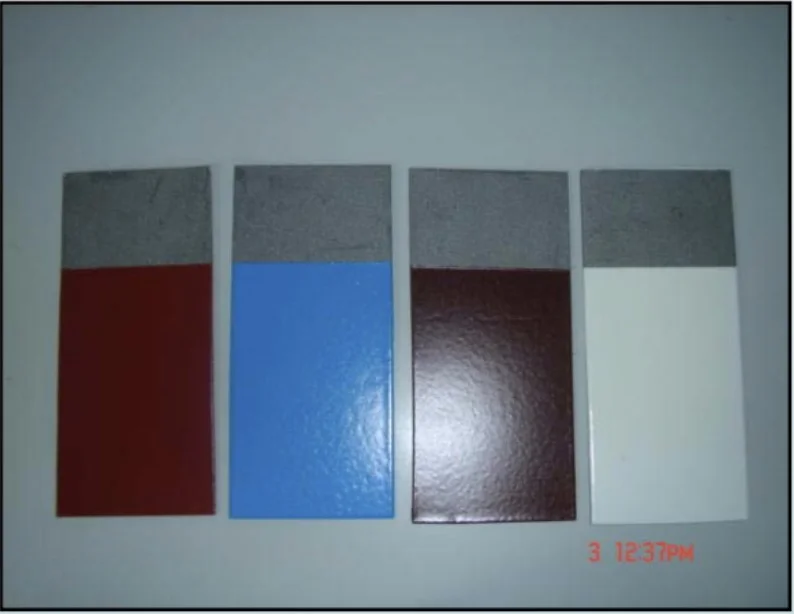

Our Metal-Coat 3-in-1 High Build Epoxy Coating combines primer, intermediate coat, and topcoat into a single advanced formulation. This innovative system dramatically reduces application time and labor costs while delivering superior corrosion protection for decks, pipelines, superstructures, and other exposed surfaces.

Repairs are performed while your vessel remains operational, eliminating costly drydocking and operational interruptions. Maintain your schedule and commitments without compromise.

Avoid drydocking expenses, lost operational revenue, and the high costs of traditional 3-coat systems. Our efficient 3-in-1 formulation and onboard service model deliver substantial savings.

Our advanced Metal-Coat systems provide 5-8 years of superior corrosion protection, extending the life of your vessel and reducing the frequency of maintenance interventions.

Our wet abrasive blasting system and efficient coating formulations minimize environmental impact, reduce material waste, and support sustainable maritime operations.

Our portable equipment and small team footprint allow us to work in confined spaces and adapt to your vessel's operational constraints with minimal disruption.

CORRAST brings decades of experience in industrial corrosion protection. Our specialized team is trained in marine environments and committed to delivering exceptional results.

Let CORRAST's Marine Voyage Repairs team deliver professional corrosion treatment and coating services while your vessel remains operational.