Extending marine terminal life by 20+ years with advanced corrosion protection and inspection methods, saving millions in replacement costs.

Explore Our SolutionsWe help marine terminals extend the life of their jetties by 20+ years using advanced corrosion protection and inspection methods, saving millions in replacement costs.

Our comprehensive jetty corrosion protection solutions address the most critical challenges faced by marine infrastructure. From pipe piles to vector frames, we specialize in preventing costly deterioration through environmentally compliant methods that meet ISO 12944/NACE/IMCA standards.

Proven solutions that significantly extend jetty service life

Meets ISO 12944, NACE, and IMCA standards

Save millions in replacement costs

Corrosion can lead to costly shutdowns, frequent and expensive repairs. Our advanced corrosion solutions are environmentally compliant (meets ISO 12944/NACE/IMCA standards), reduces lifecycle budget, prevents unplanned downtimes and extend structure life by 15 years.

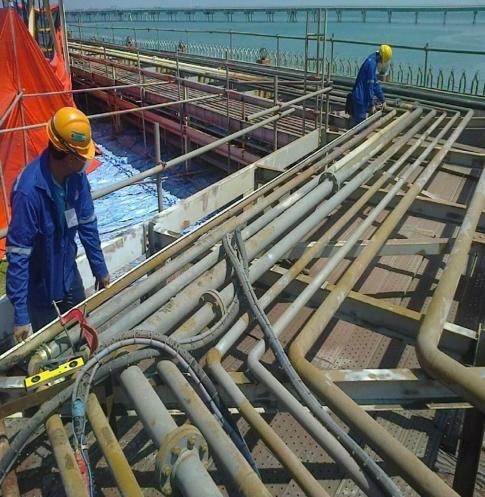

Our jetty pipe pile protection services include environmentally compliant wet abrasive blasting and application of high-performance METALCOAT underwater epoxy paint. This forms a permanent barrier underwater to resist salt, abrasion, and biofouling while being non-toxic to marine life.

We offer high performance and reliable underwater epoxy paint. It can be applied underwater with proven adhesive bonding and non-toxic to marine life. This forms a permanent barrier underwater to resist salt, abrasion and biofouling.

Corrosion can lead to Jetty Fenders failure under berthing impact, risking vessel and jetty damage. Early replacements will lead to increased installation and fabrication costs. Moreover unforeseen berth downtime and demurrage costs will impact operation.

It is therefore important to have planned maintenance and corrosion prevention works for jetty fender systems. Our specialized protection ensures your fender systems maintain their structural integrity and performance under harsh marine conditions.

Rusted steel pipelines causing leaks will result in loss of product containment, environmental fines, jetty shutdowns, structural weakness and severe safety risks. Replacing jetty pipelines can cost millions.

We help you assess, rehabilitate, and protect existing pipelines to safely extend their service life by 10 years — without shutdowns or drydocking. Our METALCOAT 3-in-1 solution provides comprehensive protection for jetty pipeline systems.

Our advanced METALCOAT 3-in-1 system provides comprehensive pipeline protection with superior underwater performance. This innovative coating system offers exceptional resistance to corrosion, chemicals, and marine growth while maintaining structural integrity without requiring shutdowns or drydocking.

Rusty jetty crash barriers are often critical safety assets that get ignored until they fail. Corrosion turns a crash barrier from a safety device into a liability.

A rusty barrier might not stop a vessel — it could collapse and damage both ship and jetty. We ensure your jetty crash barriers stay strong, safe, and seawater-resistant — by engineering corrosion protection systems that extend life and prevent catastrophic failure.

Crash barriers are essential safety devices that prevent vessels from colliding with critical jetty infrastructure. Corrosion compromises their structural integrity, potentially leading to:

Rusty jetty vector frames (i.e., the steel support frames that carry fenders, loading arms, or approach structures) contain hidden structural hazards that can quietly compromise safety, mooring capacity, and fender performance.

They're constantly exposed to splash zone corrosion, UV, and mechanical stress — and are usually painted only once during installation. Our comprehensive protection systems address these critical support structures that are often overlooked until failure occurs.

Vector frames face multiple corrosion challenges:

Comprehensive three-stage approach to jetty corrosion protection and life extension

Our jetty corrosion engineering experts provide customized solutions to extend asset life by 20+ years and ensure safety compliance

Request a Consultation