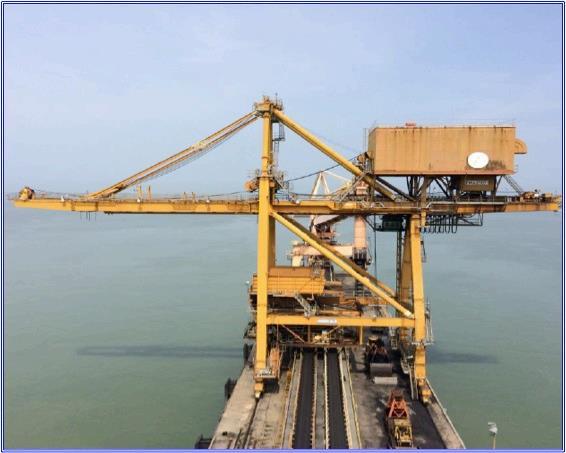

Extending crane life by 10+ years using marine-grade systems proven in high-salinity environments

Explore Our SolutionsWe specialize in corrosion engineering for critical port infrastructure like quay and RTG cranes. Our team not only repairs and protects steel structures, but extends crane life by 10+ years using marine-grade systems proven in high-salinity environments. We can provide a free corrosion audit to show where your risk hotspots are—and how to reduce downtime and repair costs long term.

We have extensive experience in Singapore ports, Malaysia ports, and offshore oil platforms. The professional work and advanced metal coatings had proven to prevent disastrous collapse and costly rebuilds. Our comprehensive crane corrosion protection solutions address the most critical challenges faced by port infrastructure through environmentally compliant methods that meet ISO 12944/NACE/IMCA standards.

Proven marine-grade systems that significantly extend crane service life

Specialized solutions for harsh marine environments

Identify risk hotspots and reduce long-term costs

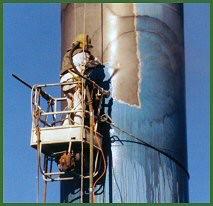

Corrosion can lead to costly crane downtime, frequent repairs, and potential catastrophic failures. Our advanced wet abrasive blasting process removes existing corrosion and prepares surfaces for optimal coating adhesion, extending crane structural life by 10+ years.

We have extensive experience in Singapore ports, Malaysia ports, and offshore oil platforms. The professional work and advanced metal coatings had proven to prevent disastrous collapse and costly rebuilds. Our environmentally compliant wet abrasive blasting process ensures proper surface preparation for maximum coating performance.

Our advanced METALCOAT 3-in-1 system provides comprehensive crane protection with superior performance in high-salinity marine environments. This innovative coating system offers exceptional resistance to corrosion, UV radiation, and mechanical stress while maintaining structural integrity.

The METALCOAT 3-in-1 system is specifically formulated for port infrastructure applications, providing long-lasting protection that prevents costly crane downtime and extends service life significantly. This proven solution has been successfully applied to quay cranes and RTG cranes throughout Singapore and Malaysia ports.

Our METALCOAT 3-in-1 system provides comprehensive crane protection with superior underwater performance. This innovative coating system offers exceptional resistance to corrosion, chemicals, and marine growth while maintaining structural integrity without requiring crane shutdowns.

Our crane corrosion engineering experts provide customized solutions to extend asset life by 10+ years and ensure operational safety

Request a Free Corrosion Audit